Quality is our formula

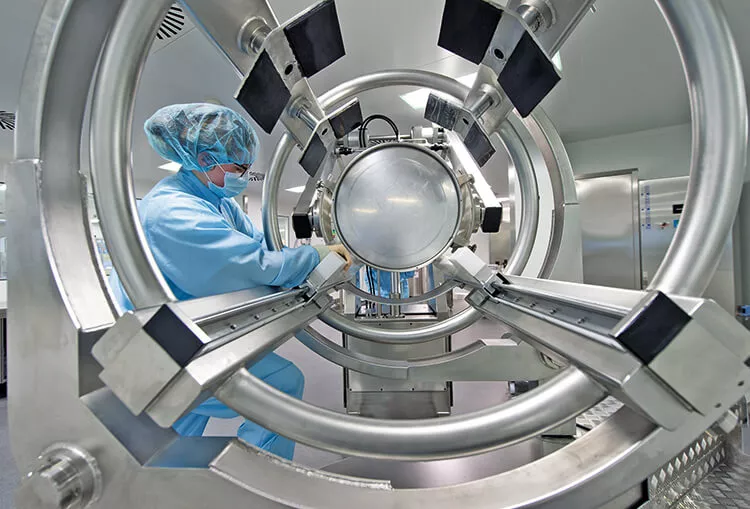

From the plant in the field to the finished preparation in the hands of the user, our goal is always to meet the strictest quality standards. Hevert preparations work naturally, are of high quality, and have very few side effects.